Israeli Tactical Robotics, Boeing tie-up to Develop Ducted Fan Technology Aircraft

Israel-based Tactical Robotics and Boeing have signed an agreement to further development of a ducted fan propulsion technology to be used in piloted and autonomous light aircraft.

The two companies will set up a joint working group to explore opportunities may exist in developing, producing and marketing Fancraft based vertical takeoff and landing (VTOL) products including Tactical Robotics’ own Cormorant autonomous vehicle.

Boeing VP international sales, Boeing global sales and marketing Dennis D. Swanson said, "this MoU with Tactical Robotics builds on Boeing’s commitment to developing and investing in innovative technologies that lead to safe, reliable aircraft around the world."

Rafi Yoeli, CEO of Tactical Robotics’ parent company Urban Aeronautics said, "Cormorant represents the first in a family of vertical takeoff and landing aircraft that can fly and land where no other aircraft can. We can think of no better partner than Boeing to help us develop this product and utilize the Fancraft technology to its full potential."

Aviation ducted fan technology, also called Fancraft, uses a fan mounted in a cylindrical duct to produce thrust. This arrangement can efficiently enhance airflow velocity and pressure when compared to an open rotor. Fancraft technology improves stability, payload, speed and endurance when compared to conventional ducted fan configurations.

According to Tactical Robotics information:

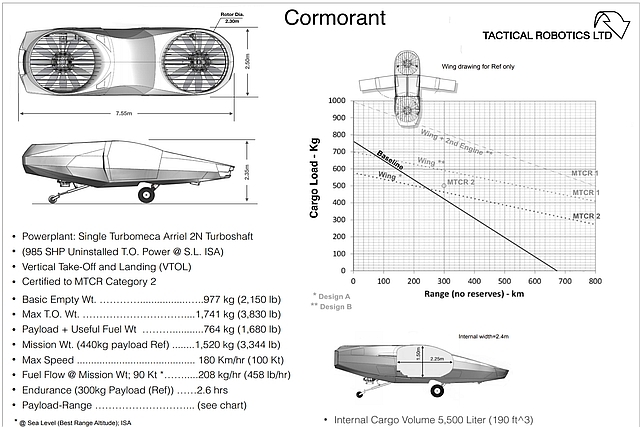

Cormorant’s internal rotor design enables it to maneuver with unprecedented precision and safety in even the most constricted areas. Its minimal footprint is only slightly larger than that of a large delivery van.

By removing the human operator from the loop on most missions, Cormorant can eliminate personnel exposure in hazardous environments.

The Cormorant is capable of ferrying 500 Kilograms of cargo per each 50 Kilometer radius sortie, thereby delivering approximately 6,000 Kilograms over 24 hours.

Cormorant can hover in place with high precision and operate in harsh weather and winds of up to 40 knots, a significant improvement over existing helicopters. The addition of externally mounted utility equipment can enhance the vehicle’s robotic functionality.

Cormorant can be optionally equipped with a rocket deployed parachute, that will safely lower the complete vehicle and its payload from almost any height in the case of an unlikely malfunction of its engine or lift rotors.