U.K. Makes 3D Printable Parts for Tempest Fighter from Old Tornado Aircraft

The recycling effort focuses on high-value strategic metals, including titanium, aluminium, and steel

In a world first, the U.K. has extracted components from retired Eurofighter Tornado aircraft, turning them into 3D-printable materials for the upcoming sixth-generation Tempest fighter jet.

As part of the Tornado 2 Tempest project, individual parts from decommissioned Tornado jets were ground down into powdered metal and repurposed for additive manufacturing. The recycling effort focuses on high-value strategic metals, including titanium, aluminium, and steel, which are commonly found in Ministry of Defence surplus assets.

Titanium components, such as jet engine compressor blades from low-pressure air compressors, were selected for the project. These parts were cleaned, atomised into fine powders, and used to 3D print new components, including a nose cone and compressor blades. The work was carried out by Additive Manufacturing Solutions Limited for Orpheus, a Rolls-Royce small engine concept linked to the U.K. Future Combat Air System (FCAS) programme.

The newly printed nose cone was fitted onto an Orpheus test engine, where it passed safety and performance assessments, demonstrating the feasibility of the recycling approach for Tempest aircraft components. The initiative aims to cut costs, enhance sustainability, and reduce reliance on global supply chains for critical materials.

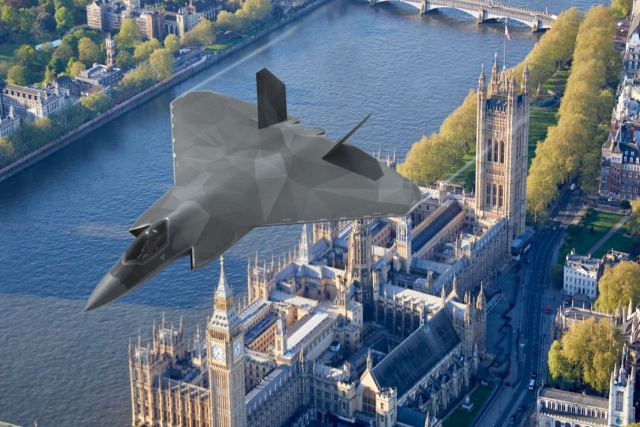

The Tempest fighter is a joint effort between the U.K., Italy, and Japan, with engineers from BAE Systems, Leonardo, and Mitsubishi Heavy Industries collaborating on its development. The aircraft, expected to enter service in 2035, is being designed as a highly adaptable, connected, and interoperable platform for future air combat operations.