DARPA-backed Startup Speeds Up Production for Radar, Electronic Warfare Amplifiers

New method cuts production time for traveling-wave tubes from over a year to weeks, supporting radar and electronic warfare systems.

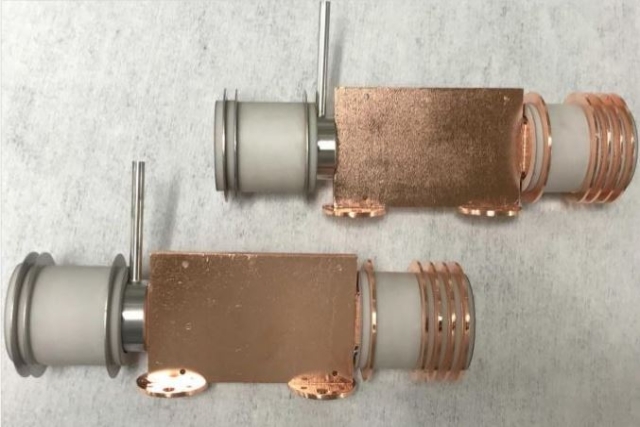

A U.S. startup, supported by the Defense Advanced Research Projects Agency (DARPA), has developed a new manufacturing process that reduces the production time for traveling-wave tubes (TWTs) from over a year to just a few weeks.

TWTs are used in high-frequency applications, including satellites, deep space communication, and electronic warfare. Their complex design and precise assembly require specialized manufacturing, which has traditionally limited supply and increased costs.

Elve, a deep-tech startup, developed the Layered Additive Multi-Material Manufacturing – Digitized (LAM3D) process through DARPA’s Small Business Innovation Research (SBIR) program. This new additive manufacturing technique enables faster production and reduces costs, making TWTs more accessible for both defense and commercial use.

The LAM3D process also allows Elve to design and optimize TWT circuits in under two hours across critical frequency bands such as Q-band (33–50 GHz), V-band (40–75 GHz), and E-band (60–90 GHz). These frequencies are essential for advanced radar systems and high-speed communication networks.

Elve’s innovation received additional support from DARPA’s Embedded Entrepreneur Initiative (EEI), which connects startups with business experts to accelerate commercialization. Through EEI, Elve refined its market strategy and raised $15 million in Series A funding to open a commercial manufacturing facility.

Building on its DARPA-supported work, Elve has expanded the LAM3D process to manufacture circuits operating above 200 GHz, meeting future demands for next-generation communication and sensing technologies.